Ultra-coarse grained cemented carbides are often used under conditions of concurrently applied stress and high temperature. Improvement of high-temperature mechanical performance of ultra-coarse grained cemented carbides is highly desirable but still a big challenge. In this study, it is proposed that the high-temperature compression strength of ultra-coarse cemented carbides can be enhanced by modulating hard matrix grains by activated TaC nanoparticles, through solid solution strengthening of Ta atoms. Based on the designed experiments and microstructural characterizations combined with finite element simulations, the grain morphology, stress distribution and dislocation configuration were studied in detail for ultra-coarse grained cemented carbides. The mechanisms of Ta dissolving in WC crystal and strengthening ultra-coarse grains through interaction with dislocations were disclosed from the atomic scale. This study opens a new perspective to modulate hard phases of cemented carbides for improving their high-temperature performance, which will be applicable to a variety of cermet and ceramic-based composite materials.

Publication:https://doi.org/10.1016/j.jmst.2021.06.067

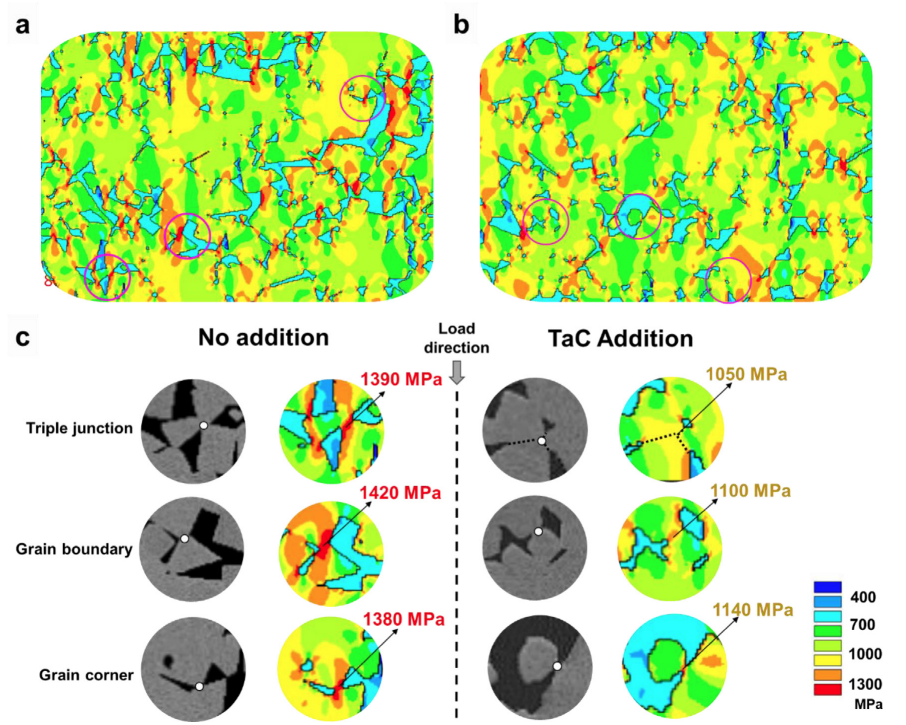

Fig. 1. Stress distributions in the microstructures of WC-8Co (a) and WC-8Co-0.8TaC (b) specimens after compression at 800°C, and comparison of the stress distribution at representative locations at WC skeleton between WC-8Co (left panel) and WC-8Co-0.8TaC (right panel) specimens (c). The local regions in (c) are corresponding to those circled in (a) and (b), respectively.

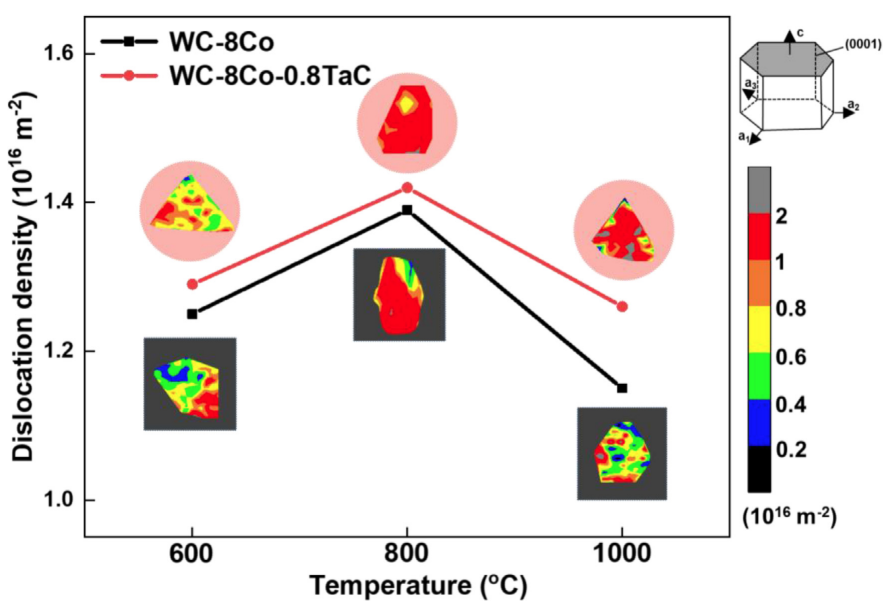

Fig. 2. Average dislocation density in WC grains and the dislocation density at (0001) WC plane in WC-8Co and WC-8Co-0.8TaC specimens compressed at different temperatures.

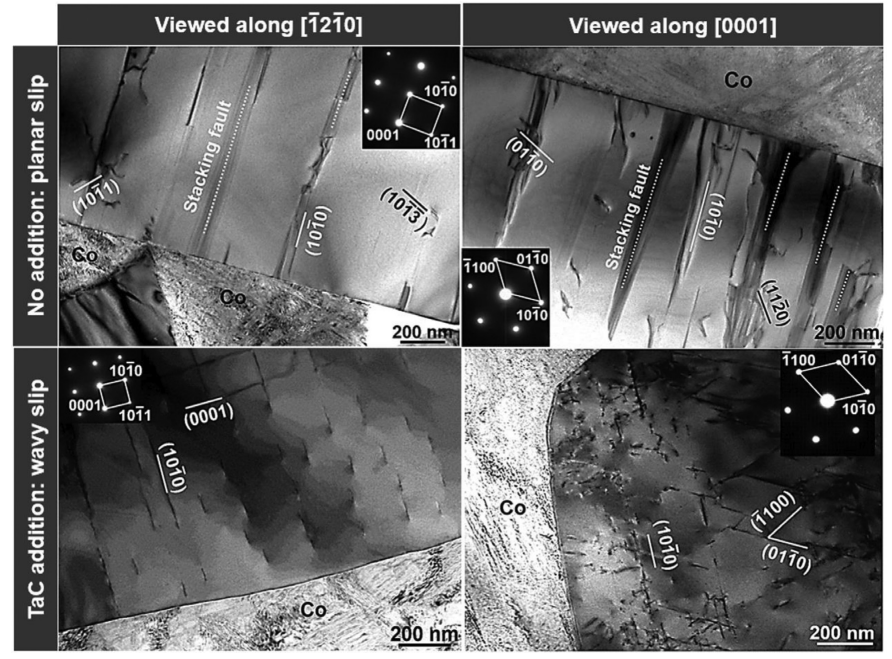

Fig. 3. Dislocations in WC-8Co (a, b) and WC-8Co-0.8TaC (c, d) specimens after compression at 800 °C, observed along [-12-10] and [0001] directions, respectively.