Ceramic-based composites generally have low fracture toughness, and toughening these materials without sacrificing their hardness has been a big challenge. This study presents an approach for toughening ceramic-based composites by modulating the strain partition and stress distribution in phase-boundary regions. A new concept of homogenizing the lattice strain to achieve high fracture toughness in ceramic-based composites is proposed based on the collective lattice shear of martensitic phase transformation. The strategy was demonstrated by ZrO2-containing WC–Co ceramic–metal composites as a prototype. The crystal planes along the WC/ZrO2 martensitic transforming phase boundaries exhibited significantly larger and uniform lattice strains compared with conventional dislocation pile-up phase boundaries with highly localized lattice strains. The homogeneous strain and stress distributions across interfaces enabled the composite to have simultaneously high fracture toughness and hardness. The “homogenizing the lattice strain” strategy proposed in this work is applicable to a broad range of ceramic-based composites to achieve superior comprehensive mechanical properties.

Publication:https://doi.org/10.1021/acsami.3c00251

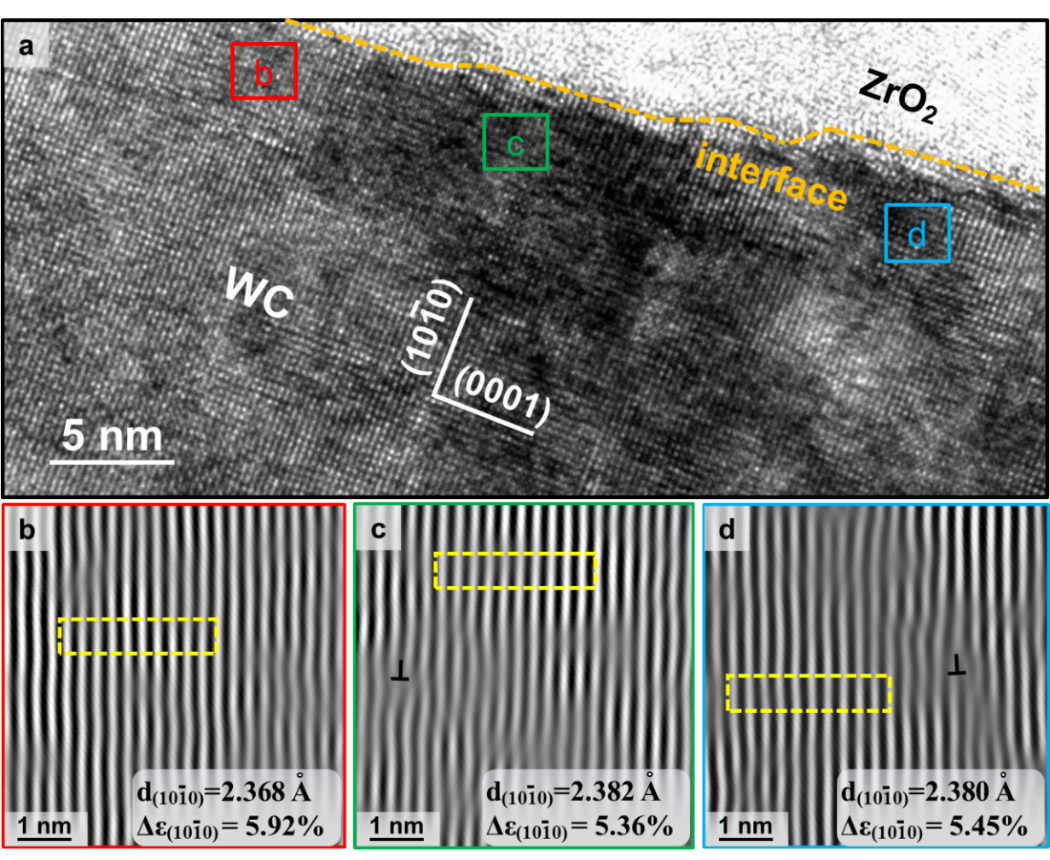

Figure 1. Analysis for the distribution of lattice strain in the (101̅0)WC plane along the WC/ZrO2 phase boundary: (a) HRTEM image of the WC/ZrO2 phase boundary, (b–d) filtered HRTEM images of the regions marked in a, dotted rectangles indicate the measured regions for the interplanar spacing and lattice strain.

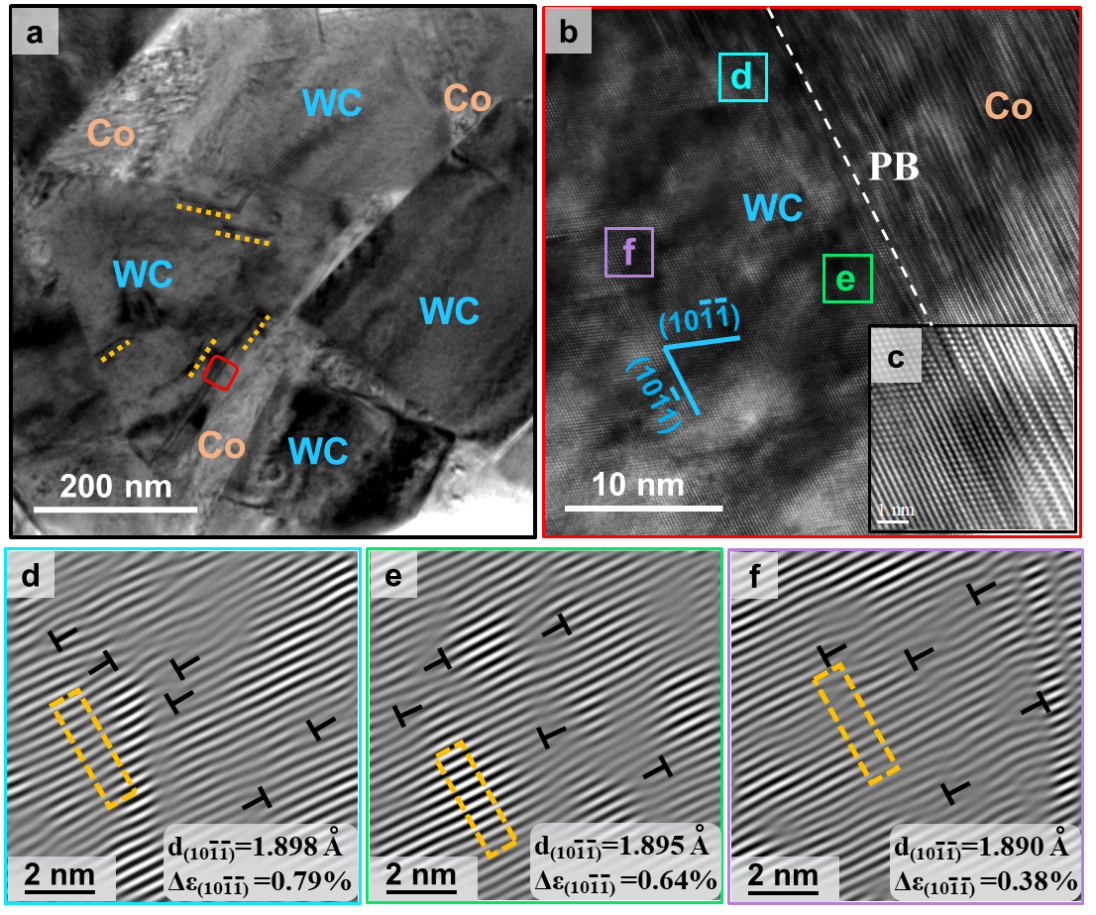

Figure 2. Analysis for the distribution of the lattice strain in the WC grain close to the WC/Co phase boundary: (a) Microstructure of the deformed region without ZrO2, (b) HRTEM image of the WC/Co phase boundary, corresponding to the region marked by the rectangle in a, (c) enlarged view of the WC/Co phase boundary shown in b, and (d–f) filtered HRTEM images of the regions marked in b; dotted rectangles indicate the measured regions for the interplanar spacing and lattice strain.

Figure 3. Analysis for the structure and lattice strain on the atomic level at phase boundaries after deformation: (a) HRTEM image of the WC/ZrO2 phase boundary, (b) lattice strain on the atomic level at the WC/ZrO2 phase boundary calculated by the GPA method (the analyzed region is the phase boundary (PB) shown in a and the selected reference region for strain calculation is indicated by “ref” in a), (c) HRTEM image of the WC/Co phase boundary, and (d) lattice strain on the atomic level at the WC/Co phase boundary calculated by the GPA method (the analyzed region is the phase boundary (PB) shown in c and the selected reference region for strain calculation is indicated by “ref” in c).

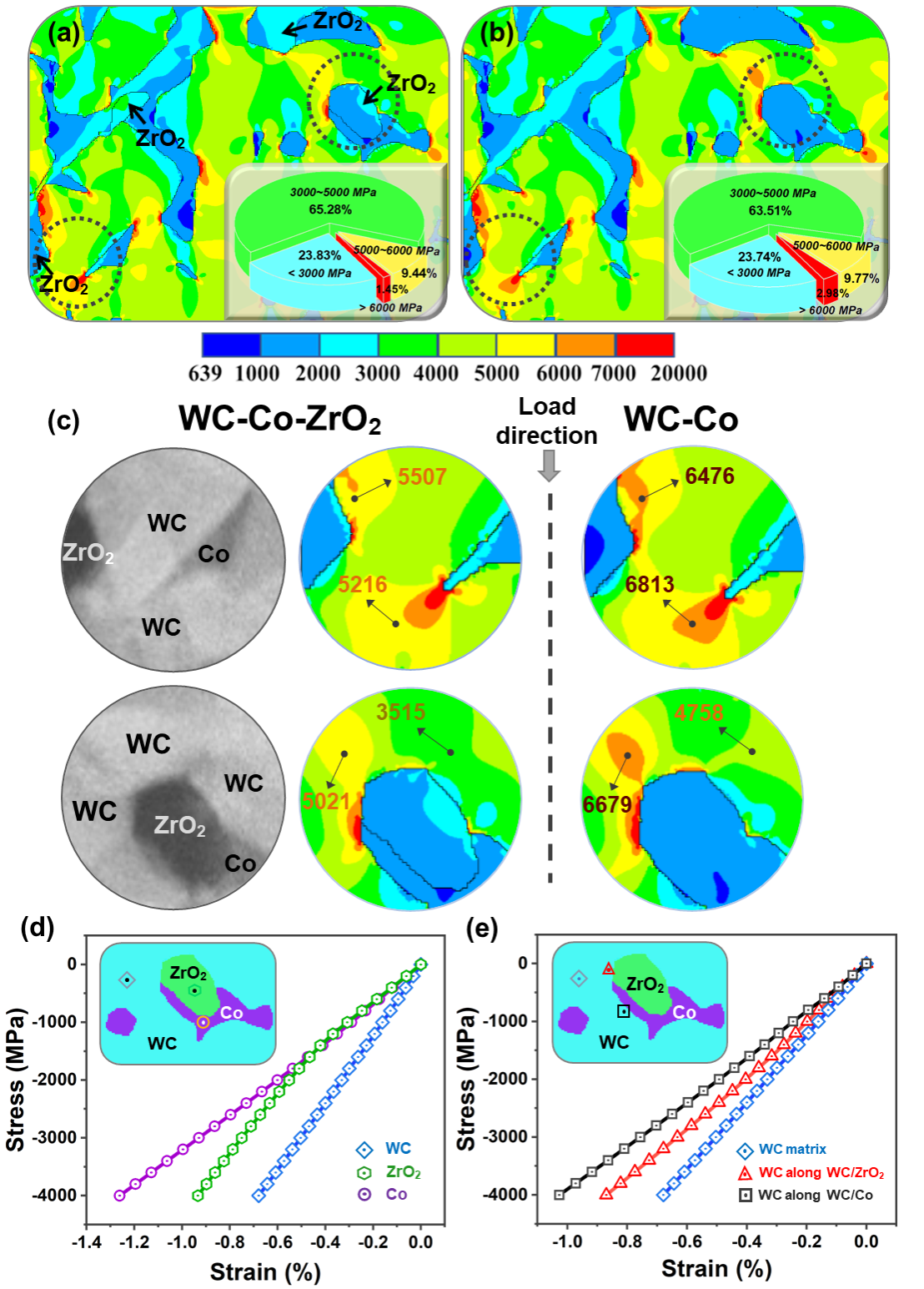

Figure 4. Stress distribution and strain response of different phases with the applied load obtained by finite element simulations: (a, b) von Mises stress distributions in WC–12Co–3ZrO2 and WC–12Co samples compressed at 4000 MPa (the insets illustrate the statistics of the stress distribution), (c) local stress distributions in the regions marked by the dotted circles in a and b, respectively, (d) strain response of different phases in WC–12Co–3ZrO2 with applied stress, and (e) strain response of WC at different locations in WC–12Co–3ZrO2 with applied stress.

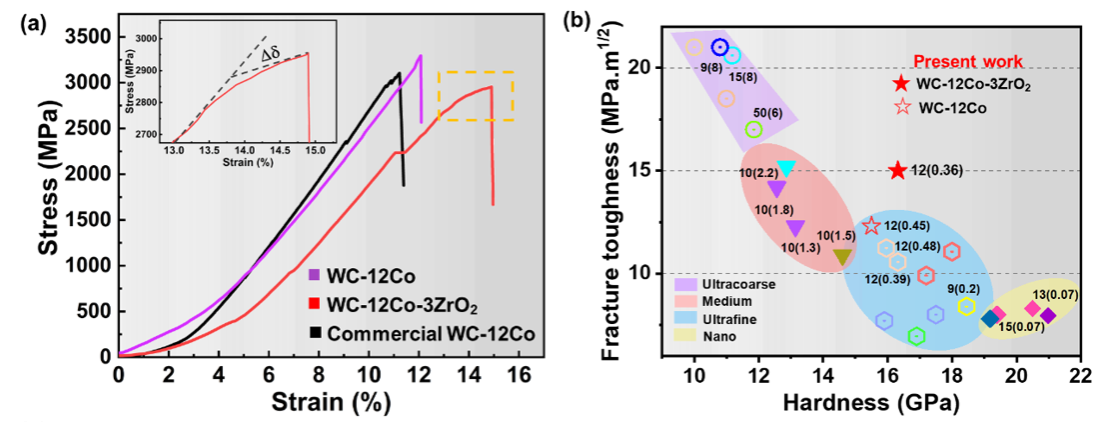

Figure 5. Mechanical properties of the WC–12Co–3ZrO2 composite: (a) stress–strain curves of the composites under compression tests; (b) comparison of the hardness and fracture toughness of the WC–12Co–3ZrO2 composite and those of the composite counterparts. (28−32) Numbers in brackets are the grain sizes of the composites in μm, and those in front of brackets are Co wt %.