Owing to high water content and homogeneous texture, conventional hydrogels hardly reach satisfactory mechanical performance. Tensile-resistant groups and structural heterogeneity are employed to fabricate tough hydrogels. However, those techniques significantly increase the complexity and cost of material synthesis, and have only limited applicability. Here, it is shown that ultra-tough hydrogels can be obtained via a unique hierarchical architecture composed of chemically coupled self-assembly units. The associative energy dissipation among them may be rationally engineered to yield libraries of tough gels with self-healing capability. Tunable tensile strength, fracture strain, and toughness of up to 19.6 MPa, 20000%, and 135.7 MJ cm⁻3 are achieved, all of which exceed the best known records. The results demonstrate a universal strategy to prepare desired ultra-tough hydrogels in predictable and controllable manners.

Publication: https://doi.org/10.1002/advs.202303315

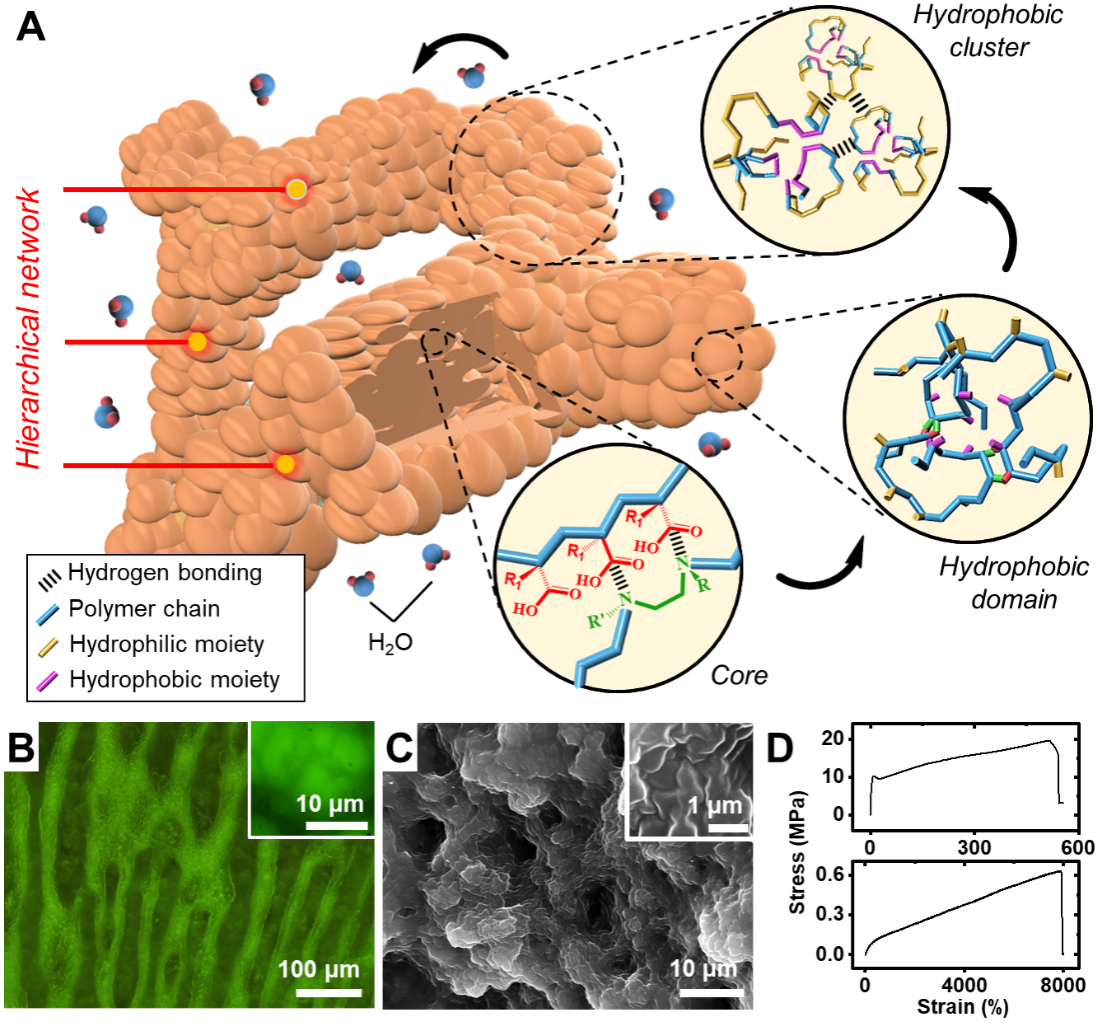

Figure 1. Formation of HEAD gels. A) The formation formula, mechanism and characteristic structure of HEAD gels. B) A representative microscopic image of HEAD gels. Inset: a magnified image of a single thread. C) A representative SEM image of HEAD gels. Inset: a magnified area of C. D) Representative tensile curves showing the extraordinary property of a couple of HEAD gels.

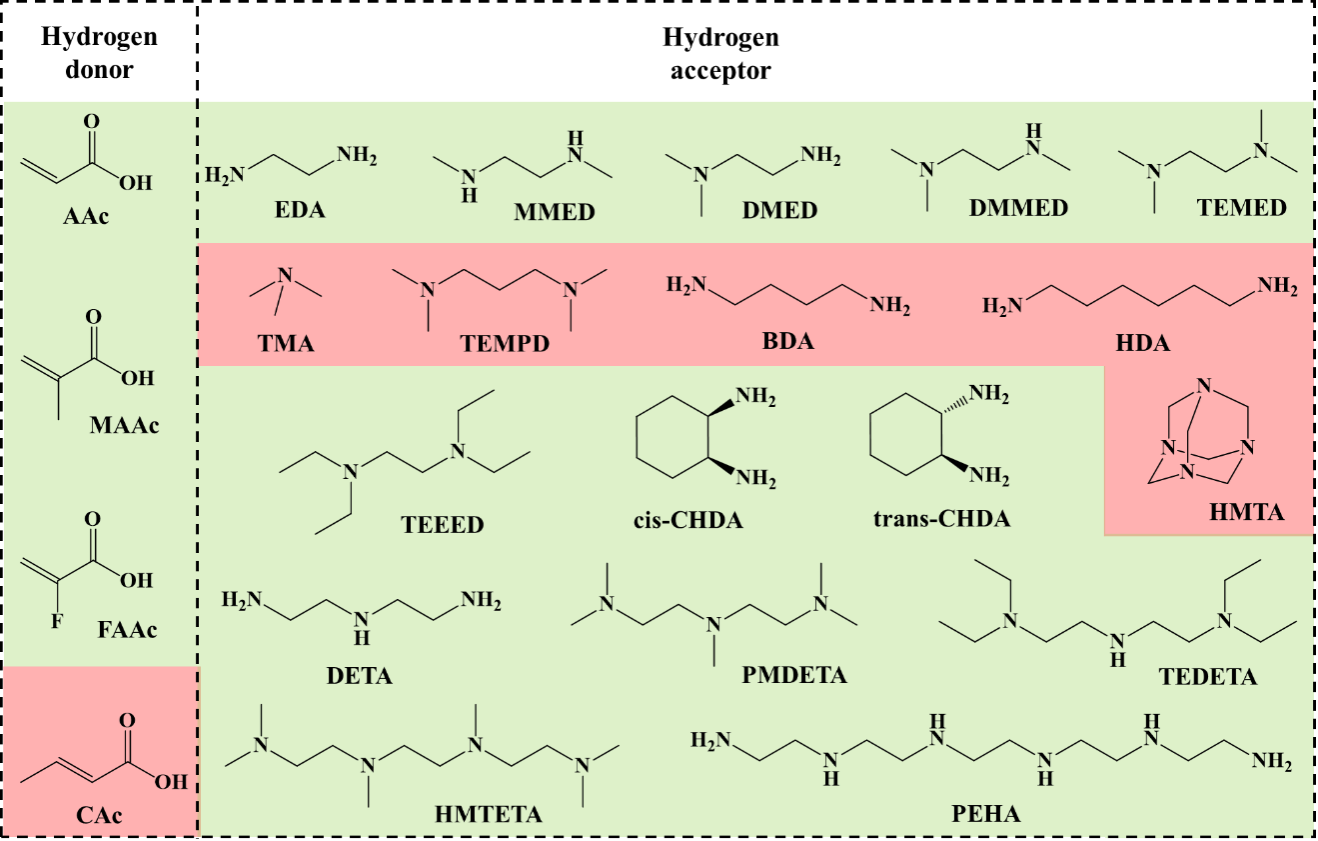

Figure 2. Reactive species tested in the preparation of HEAD gels. The green and red color indicate preferred and undesirable reactants, respectively.

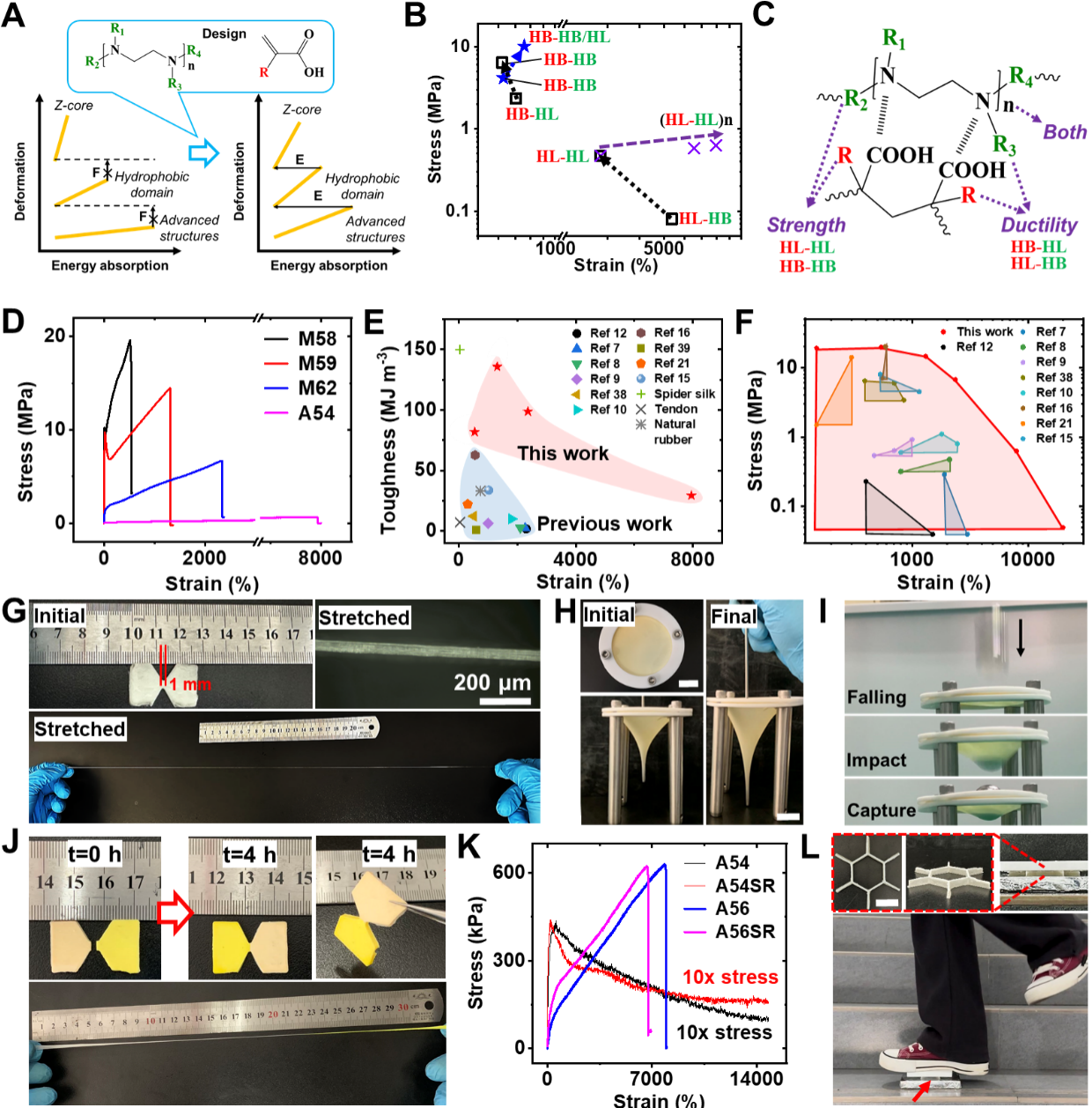

Figure 3. Extraordinary performance of HEAD gels. A) The way to synchronizing energy dissipations. B) The effect of substitutional groups’ property on mechanical performance. Red and green colors indicates substitutional group on acidic monomers and amines, respectively. C) The “molecular structure”-“mechanical property” relationship in HEAD gels. D) Tensile curves of representative HEAD gels. E) Strain level and toughness of ultra-tough hydrogels prepared by different methods. F) Tunability in fracture strain and stress (the encompassed area) of ultra-tough hydrogels prepared by different methods. G) Pictures showing the superior ductility of HEAD gels (A56). H) Pictures of a poking test of A54 gel. Scale bars: 2 cm. I) Pictures of a drop-ball test of A54 gel. J) The self-healing of A56 gel. K) Tensile curves of pristine and self-repaired (SR) HEAD gels. L) Pictures showing a 3.2 g M53 gel scaffold (pointed by the arrow) can support a 50 kg person. Insets: pictures of the scaffold sandwiched between two boards. Scale bar: 2 cm.